Every fleet manager has heard this line before:

“It was running fine yesterday.”

Yet today, the truck was stranded.

The driver is stuck.

The customer is waiting.

Operations are disrupted.

Breakdowns feel sudden, but they rarely are. In most cases, the truck gave warnings long before it stopped, but the problem is those warnings were never captured, tracked, or acted on.

This is exactly where fleet maintenance software changes the outcome.

Breakdowns Are Not Random, They Are Missed Signals

A breakdown is usually the final stage of a long process.

Before the failure, there are signs:

- Gradual overheating

- Increased vibration

- Uneven tyre wear

- Longer braking distance

- Repeated minor repairs

Individually, these don’t stop trucks. Together, they always do it.

When inspections are inconsistent or disconnected from maintenance action, these signals disappear into daily operations, until the vehicle fails.

Why Traditional Inspections Don’t Prevent Failures

Most fleets already perform inspections.

The issue is not intention, its structure.

Common problems:

- Inspections are rushed

- Findings are written but not followed up

- No connection between inspection and repair

- No history of repeat issues

- Maintenance happens only after failure

An inspection that doesn’t lead to action is documentation, not protection. This is where maintenance tracking becomes more important than the inspection itself.

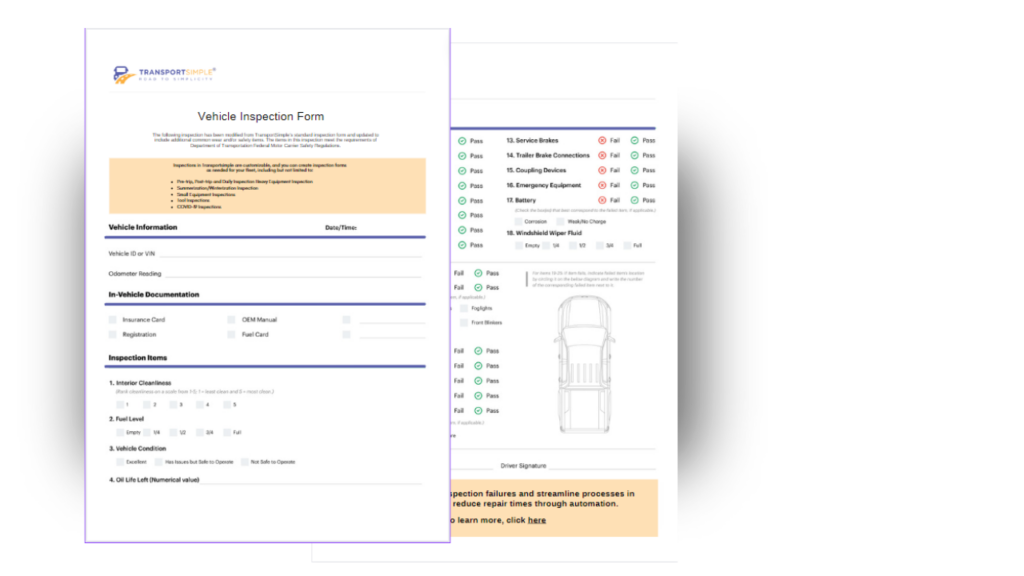

What Makes Inspections Actually “Smart”

Smart inspections are not about adding more checks. They are about closing the loop between inspection, repair, and cost.

1. Inspections Are Triggered Automatically

- Smart systems schedule inspections based on:

- Distance travelled

- Time intervals

- Vehicle usage

No dependency on memory. No reliance on manual follow-ups.

2. Issues Are Captured Clearly

Instead of vague comments, inspections record:

- Specific component issues

- Severity level

- Visual proof when needed

This removes uncertainty and speeds up decisions.

3. Findings Convert Directly into Action

This is the biggest difference.

When an issue is detected:

- A repair task is generated

- Responsibility is assigned

- Labour and parts are tracked

- Vehicle service history is updated

This connection between inspection and repair is what prevents breakdowns, not the inspection alone.

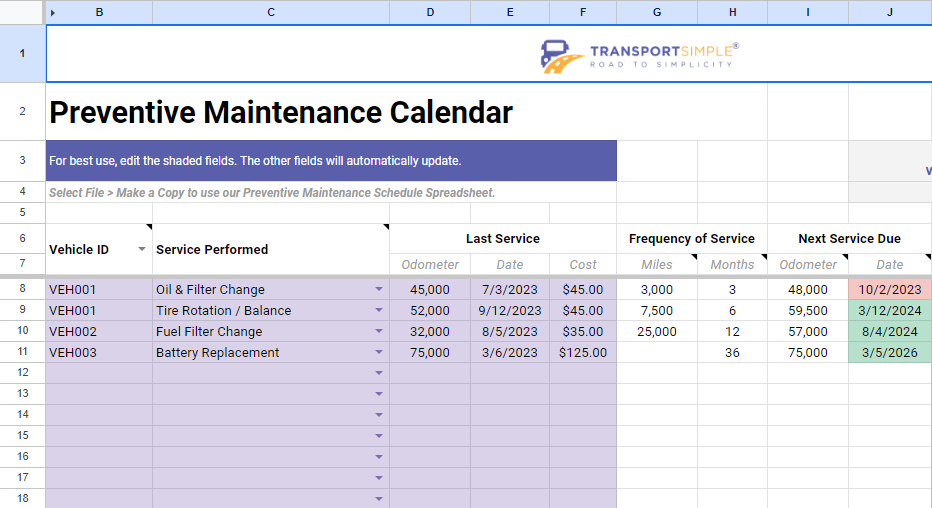

Preventive Maintenance Software: Fixing Problems Early

Reactive maintenance always costs more.

Emergency repairs:

- Disrupt schedules

- Cost more than planned work

- Increase downtime

- Create stress across teams

Preventive maintenance software focuses on fixing issues before they become emergencies.

By acting early, fleets:

- Reduce roadside failures

- Plan maintenance during idle time

- Control repair costs

- Extend vehicle life

Preventive maintenance is not about doing more work; it’s about avoiding unplanned work.

WhyWork Order Management Matters After Inspections

Many fleets record inspection issues but stop there. Without execution, data has no value.

This is why work order management software is critical:

- Every issue becomes a task

- Every task has an owner

- Every repair has a cost

- Every vehicle builds a service record

Now maintenance decisions are based on facts, not assumptions.

What This Means for Decision Makers

If you’re responsible for operations, your priorities are clear:

- Trucks available when needed

- Minimal disruption

- Predictable maintenance

Smart inspections supported by fleet maintenance software reduce:

- Unplanned downtime

- Emergency repair costs

- Operational chaos

You don’t need to analyze reports daily. You need confidence that vehicles won’t fail without warnings.

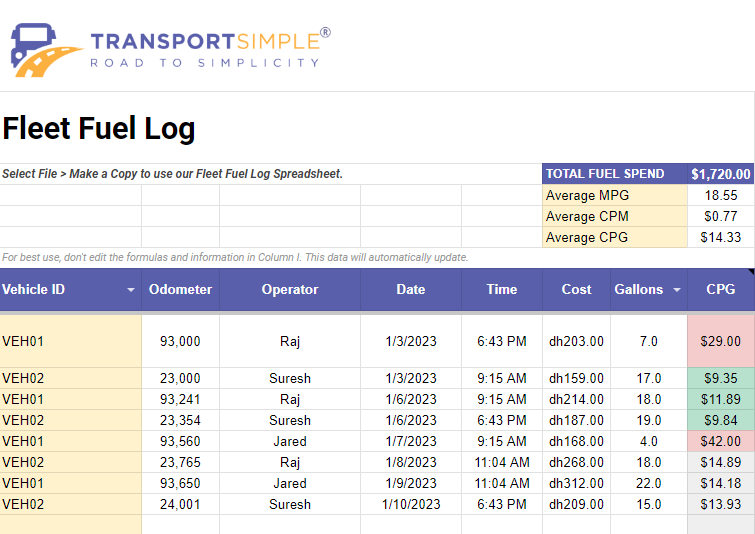

Why Influencers Push for This Change

Operations and maintenance leaders usually know where things go wrong.

They see:

- Certain trucks breaking down more often

- Repeat repairs on the same components

- Jobs that look profitable but quietly lose money

What’s missing isn’t experience, it’s proof.

Most decisions stall because there’s no:

- Historical data to point at

- Clear cost visibility per vehicle

- Pattern showing repeat failures over time

This is where maintenance tracking changes the conversation.

Instead of opinions, leaders can show:

- Vehicle-wise maintenance cost trends

- Downtime linked to specific assets

- Repeat issues backed by service history

That shift from instinct to evidence is what drives real operational change.

It’s also a theme frequently highlighted by Jasdeep Singh, who often points out that most fleet problems aren’t hidden; they’re just scattered across paperwork, calls, and disconnected systems. When data is brought together, decisions stop being emotional and start being obvious.

For influencers inside an organization, this kind of visibility is powerful. It turns conversations from “I think” to “Here’s what’s actually happening.”

Adoption on the Ground: Less Chaos, Not More Work

A common fear is that better systems increase workload.

Smart inspections reduce:

- Phone calls

- Follow-ups

- Confusion

- Last-minute firefighting

Drivers and technicians prefer systems that:

- Are quick to use

- Reduce breakdown stress

- Prevent repeat problems

Good systems simplify work; they don’t complicate it.

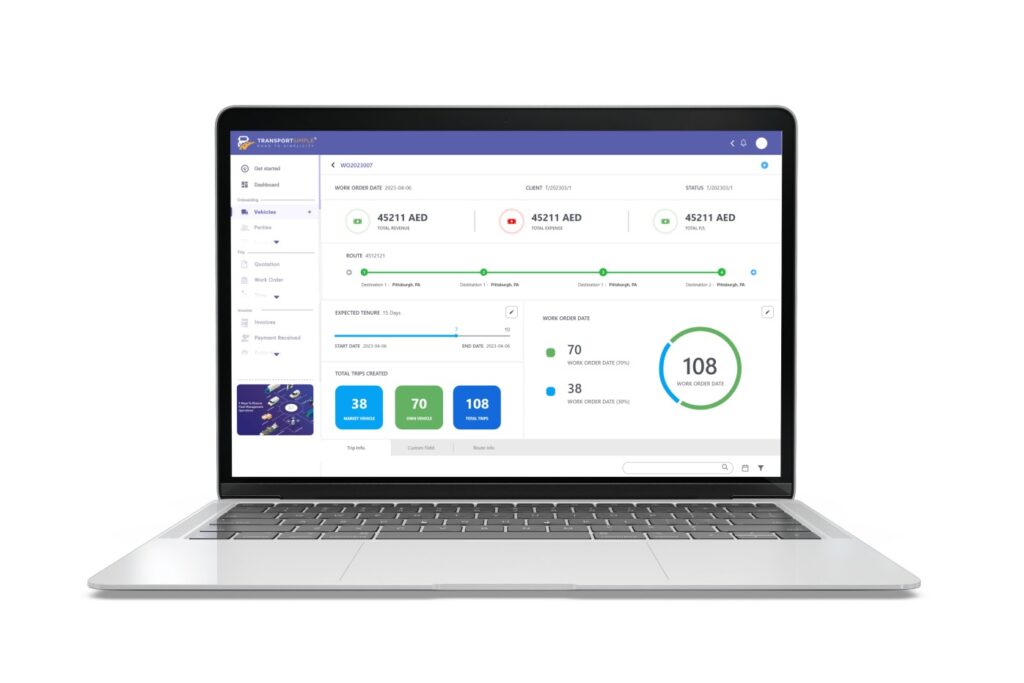

Why Fleet-Specific Systems Outperform Generic Tools

Generic software can log tasks; it doesn’t understand vehicles.

Fleet-focused platforms like TransportSimple are built around:

- Usage-based wear

- Preventive schedules

- Maintenance cost tracking

- Vehicle-level service history

This context is what turns inspection data into operational control.

The Real Outcome of Listening Early

When inspections are structured and connected:

- Breakdowns decrease

- Maintenance becomes predictable

- Costs stabilize

- Operations regain control

The biggest benefit isn’t savings alone; it’s confidence.

Final Thought

Your trucks are already communicating through wear, heat, noise, and patterns. Fleet maintenance software doesn’t add complexity. It adds clarity.

Listen early, and maintenance stays manageable. Ignore the signals, and the road will eventually force you to stop.

About this page

This page is created by the TransportSimple team.

The insights shared here come from real conversations with fleet owners, transport managers, and drivers who deal with daily challenges like breakdowns, missed inspections, and operational pressure. Over time, we’ve spoken with 100+ fleet owners across different countries and fleet sizes, and one thing is clear the problems may look small at first, but they repeat everywhere.

These blogs are written by observing patterns from those real experiences: where inspections get skipped, where issues go unnoticed, and what disciplined fleets do differently to stay in control. The aim is not to give theory, but to share practical thinking that actually works on the ground.

This same learning process shapes how TransportSimple is built by listening closely to fleet teams and quietly supporting better inspection, maintenance, and control without adding complexity.

At the end of the day, these blogs are written with a clear purpose: to help fleet owners reduce daily firefighting and build operations that are stable, organised, and easier to manage by recognising issues early and resolving them before they affect safety, uptime, or business continuity